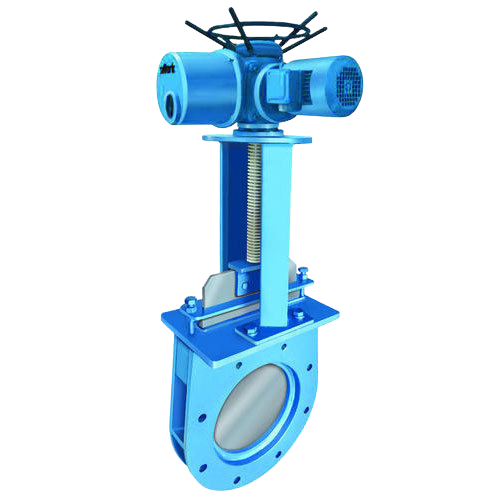

A knife gate valve works by allowing thick media to easily flow over soft seals with no interference. They work by chopping up the media as it passes through the valve. This makes it easier for the valve to handle thick flows of media including grease, oils, slurry, waste water and paper pulp.

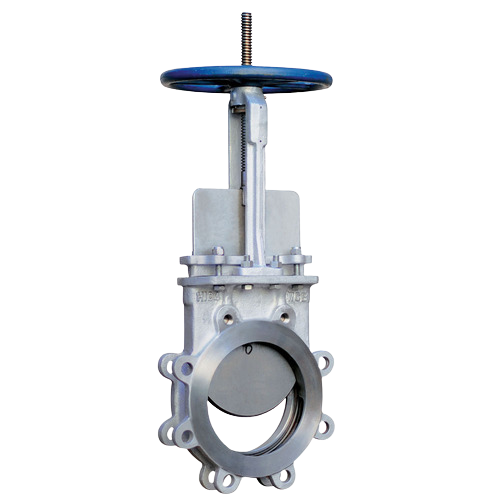

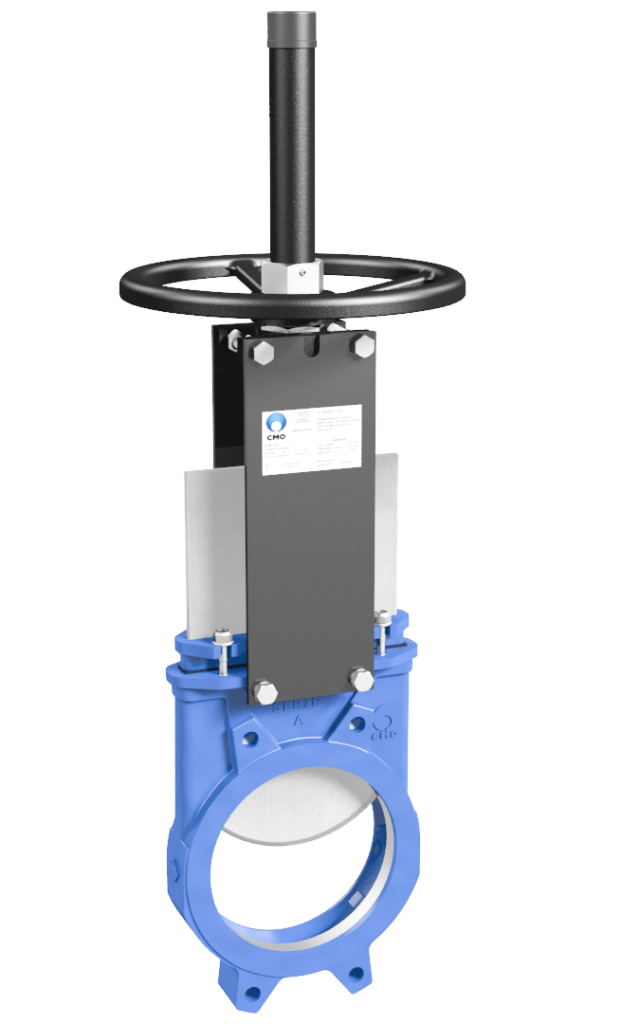

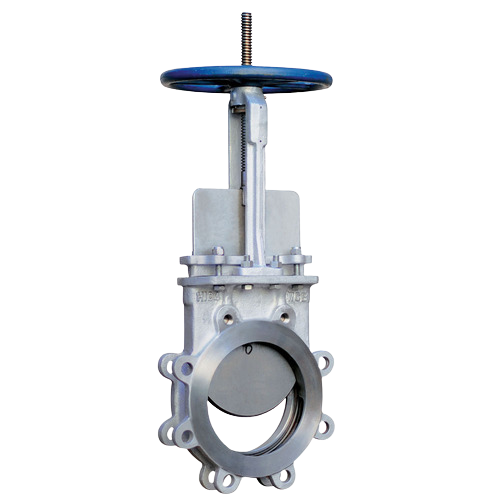

One of the differences between the gate and the knife gate valves, is that the knife gate valve often has a sharpened disc to better cut through slurry/viscous media. Also, the knife gate valve has a short face-to-face length compared to a gate valve, which is dimensionally wider. As a consequence, a knife gate valve is light weighted compared to a gate valve. These are the main differences and probably two of the biggest advantages of the knife gate valve.

A knife gate has a very thin profile compared to its bulkier counterpart. It’s also uni-directional (though bi-directional is an option on some), and comes in either wafer or lugged body, no flanges. The seats on the knife gate valve come in everything from metal to resilient types.

Cast carbon steel

cast iron

ductile iron

gunmetal

nickel

alloy steels

stainless steel

forged steels