A Leading Brand name in Industrial Valves in India

- +91 95744 88845

- info@kbsvalves.com

- Ahmedabad, Gujarat, India

AN ISO 9001:2015 CERTIFIED COMPANY

a unit of kbs brands industrial valves

- Home

- About Us

Kesharbhawani Engineering Private Limited

An ISO 9001:2015 Certified Brand

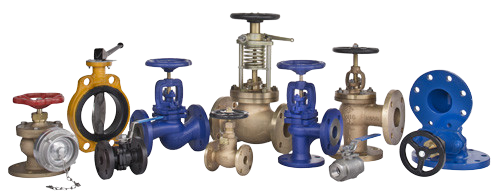

The Leading Brand Name as A Manufacturer, Suppliers & Exporters of Industrial Valves in India.

Company Profile

Know more about KESHARBHAWANI ENGINEERING PRIVATE LIMITED and what we do and how we work.

Our management

We have some unique talent in the industry from manufacturer to supplier product.

Our aim & goals

Here is Some information about our future goals and targets.

infrastructure

We are manufacturer of Valves and Fittings and we have facility for the same.

- Products

- Ball Valves

- Butterfly Valves

- Gate Valves

- Check Valves

- Globe Valves

- Safety Valves

- Diaphragm Valves

- Jacketed Valve

- Strainers

- Pulp Valves

- Lined Valves

- Forged Valves

- Sight View Glass

- Industrial Flanges

Ball valves

We have Wide Range in Ball Valves With Various Types of Products Range.

safety valves

We have Wide Range in Safety Valves With Various Types of Products Range.

strainers

We have Wide Range in Strainers Valves With Various Types of Products Range.

Jacketed Valve

We have Wide Range in Jacketed Valves With Various Types of Products Range.

butterfly valves

We have Wide Range in Butterfly Valves With Various Types of Products Range.

check valves

We have Wide Range in Check Valves With Various Types of Products Range.

pulp valves

We have Wide Range in Pulp Valves With Various Types of Products Range.

sight view glass

We have Wide Range in Sight View Glass With Various Types of Products Range.

gate valves

We have Wide Range in Gate Valves With Various Types of Products Range.

knife Gate Valves

We have Wide Range in Knief Gate Valves With Various Types of Products Range.

lined valves

We have Wide Range in Lined Valves With Various Types of Products Range.

industrial flanges

We have Wide Range in Industrial Flanges With Various Types of Products Range.

globe valves

We have Wide Range in Globe Valves With Various Types of Products Range.

diaphragm valves

We have Wide Range in Diaphragm Valves With Various Types of Products Range.

forged valves

We have Wide Range in Forged Valves With Various Types of Products Range.

Pneumatic & Electrical Valves

We have Wide Range in Pneumatic & Electrical Valves With Various Types of Products Range.

- Quality

- Applications

- Blogs

- Our Office

AN ISO 9001:2015 CERTIFIED COMPANY

a unit of kbs brands industrial valves